Combat Boots

Combat Boots

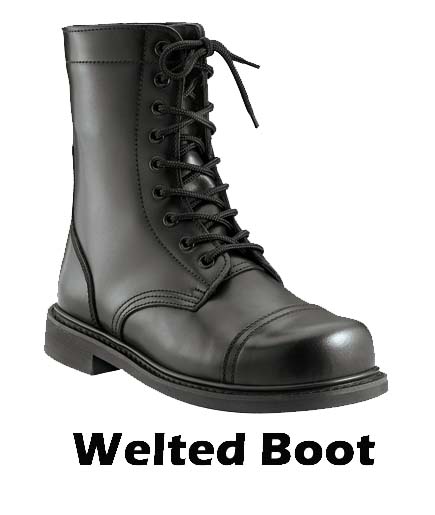

Boots used by the military have evolved with the passage of time. Originally boots were made out of leather, and the heel, and sole were, sewn, and attached with nails, and glue this process would also be called welted. One problem with the old boots is that they could not resist water exposure.

In the Vietnam War, it became obvious that the old combat boots were not good for high humidity areas, since they would fall apart after being used for only a short time. This problem brought vulcanized boots since they could resist wet environments much better than boots with welted soles. Another advantage of vulcanized boots is that it is cheaper to manufacture since the machine automatically creates and bonds the sole to the boot.

The vulcanization process uses high heat and bonding chemicals to

permanently attach rubber to other materials.

The vulcanization process uses high heat and bonding chemicals to

permanently attach rubber to other materials.

One problem with vulcanized or DMS (Direct Molded Sole) soles is that once the sole is worn out, you can not attach a new sole to the boot. However this is not a big problem since usually by the time the sole is worn out, the upper part of the boot is no good.